The wires for the marker lights are of course too short and the bullet connectors are too big.

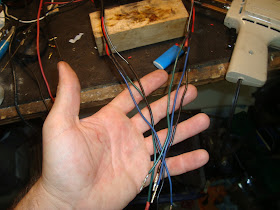

So I got these from Radio Shack and they should to the trick.

They need cleaned up a bit.

This is a bit tedious, but I only need to do it six times.

More rosin and solder.

After a fit check, I think they need to be shorter to fit inside the shrink wrap on the stock connectors. No problem.

All done.

A new wire to feed the spotlight switch.

I'm using push mount wire ties on the lightbar. Anybody need some of these? I really can only use two, but I had to buy like 200.

But they work like they should. Leave those loose for now.

More shrinkwrap.

Nice and tidy. I wanted to hide the wires in the spotlight bar, but that was not going to happen given the size of the tube.

Next we have these wire ties.

They will mount to the bolts sticking out here. I had to get longer bolts. Put on the regular nuts, then the wire ties and then another nylon lock nut.

Oops, I need more shrinkwrap.

One ground wire is too short, too. So I'll piggy back it to another ground wire.

With the wires back in the headlight it's time to get to business. I'm putting a ground junction on bolt and nut in the bucket. This is the hardwired ground to connect the rest of the ground to, because I doubt a body ground will work with all the powdercoat.

Marker light connections.

New connection from the headlight "on" wire to the switch for the spotslights.

I like these connectors with a double spade terminal.

Marker lights seem to work.... but the left one is giving me problems and acting sporactic.

Ground was loose. I don't think you are supposed to take these apart so many times.

Easy enough fix. Rosin the wire and resolder, no extra solder needed.(I'm using the clip as heat sink so the grommet and wrap don't get too hot.)

I put it back together and still had problems and messed with it some more and started popping fuses. Yep, shorted one contact wire and almost broke off the contact tip. I couldn't find any contact tip pieces so I bought a new pigtail. Of course both contacts will need to be replaced, because the holes in the bases are different.

No pictures of how I did it, because it took two hands and my wife's two hands to make it work. I cut the contact with a tiny bit of wire off the pig tail. Stripped the wire and applied rosin. Then I presoldered that wire. I rosined the wire on the bike and then held the presoldered wire next to the bike wire and heated it until solder flowed between them and then I moved the iron. Amazingly that seemed to work.

No comments:

Post a Comment