I've been running without a neutral light on the Shovelhead since I build it, but going to be putting on foot clutch and I figure a neutral light couldn't hurt at least until I figure out how to ride a suicide shift. So here's the switch, terminal, and a Kawasaki turn signal indicator.

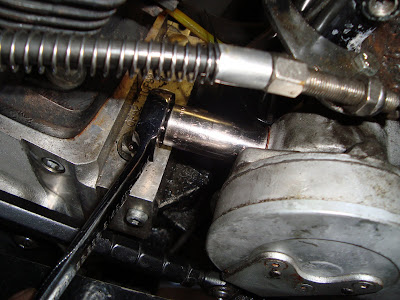

The old switch was bad so it's got to go. You need a deep socket, but there's not enough room for a rachet though. So a 5/8 inch spark plug socket and ratcheting wrench work great.

Test the new switch. It should go to ground when the bike's in neutral.

Open when in gear.

Solder the terminal to a wire.

Connect terminal and run wire to the dash.

This is probably not a great idea. I jammed both the voltage meter spade and neutral light spade into the same powered terminal.

The ground from the switch completes the circuit and the light works. It says oil, but I know it's neutral.