So, I'm blowing engine crank seals as fast as

I can put new ones in. I know my

breather timing is correct. But after talking to a bunch of people, I'm suspecting crankcase pressure is still the problem. I have heard of removing the screen from the breather gear, but I was hoping not to have to. Here's was the instructions from the S&S Sidewinder kit says though.

Time to drive fast and take chances I suppose. Let's get going.

Pushrods come out first.

Do that three more times.

Points cover off next.

Lots of "glitter" in there. That's not good.

Double check the marks for timing.

Remove the points plate.

Glitter.

Cone cover bolts.

Oops. This bolt needs to come off before the cone cover.

This is where the glitter came from. I guess I need a new set of weights, too.

ugh, wear spots.

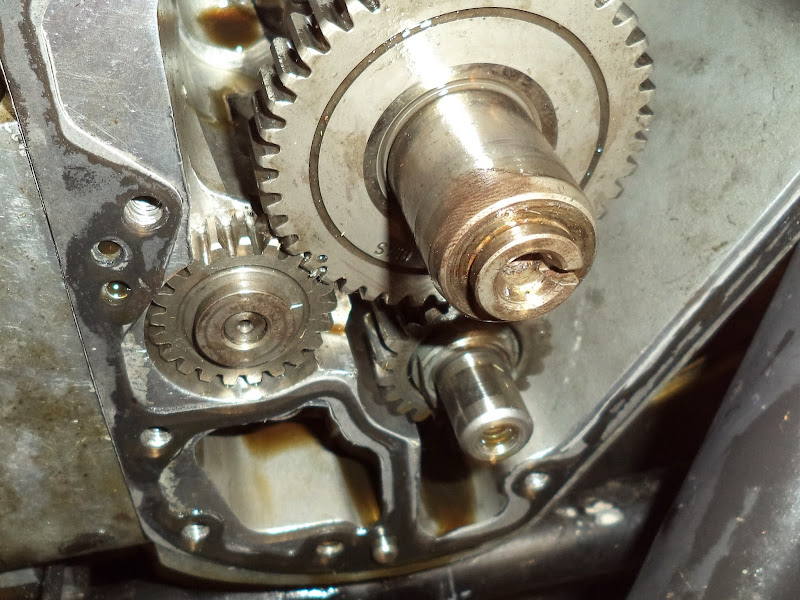

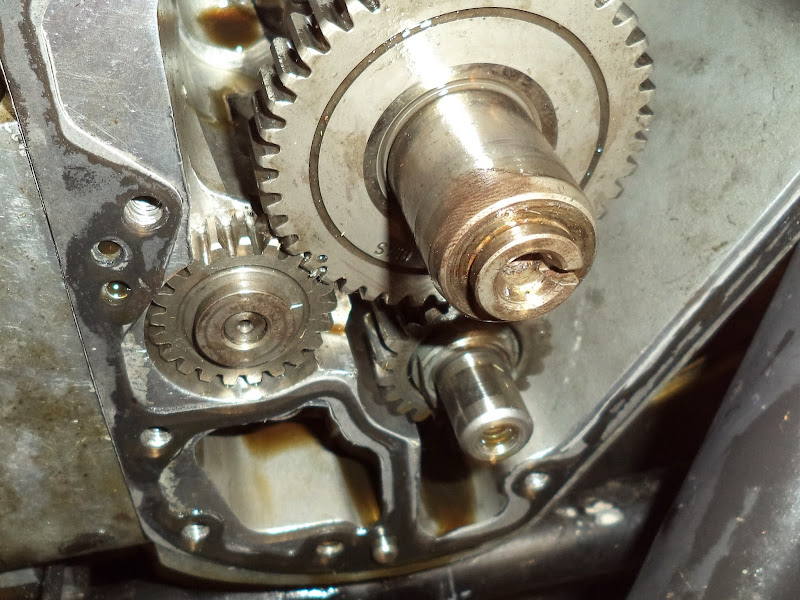

Finally down to the goods.

I'm dumping this part. It wasn't what I needed and it's not helping it breathe either.

Don't lose this shim, it is for the breather gear.

Note the timing marks because I know they aren't stock.

I pulled the cam, but probably didn't need to.

Pulled the breather gear.

Screen needs to go.

I used a scratch awl to pop one end loose.

Grabbed the loose end with needle nose pliers and kept twisting.

Out it came.

Worked the cam back in. That's a way tougher job than it should be.

Fresh gasket.

Bolt cheat sheet.

Criss-cross install and torque.

Dang forgot the shim.

Open it back up and install the shim.

Re-install the cone cover and pushrods. I can't finish because I need new ignition weights,