I was trying to remember how to get this back together. The oil filter and buddy pegs make things a trick for sure. First we removed the back plate bolts.

We then swung the plate out to the left.

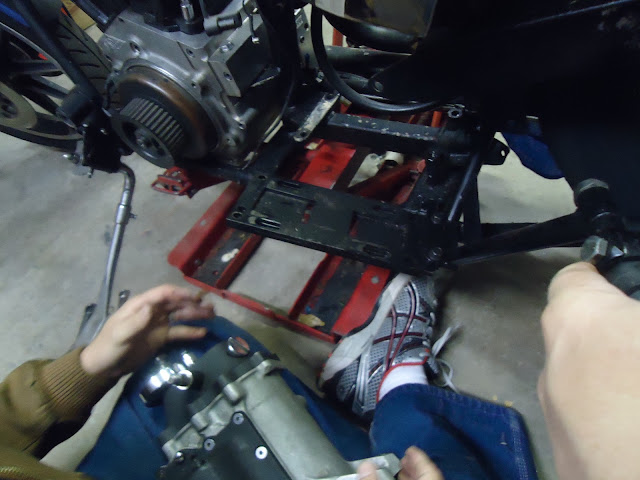

I held the peg and Columbus dropped the transmission onto the plate.

With the studs in the slots of the plate, we could swing the whole mess back into place.

This is the main part that I was dreading. It was a ton easier with Columbus' help. Thanks again.

Back plate bolts here.

Front plate bolts here.

Start into the primary side.

Bearing support plate.

Washers, lockwashers, nuts, and key in place.

Slide the clutch hub on then give it a whack to seat it.

New seal for the hub nut and drive it in.

New tab washer.

Nut goes on. LEFT HANDED THREADS.

Attached holder tool and find the proper socket.

Tighten the nuts on transmission studs to hold it still for torquing the hub nut.

Torque spec.

Then we figured out that my big torque wrench doesn't work going to the left.

We got it plenty tight, but were a bit concerned that the hub was not far enough onto the mainshaft taper.

We used to grease to see how far it fit and if it was square.

Then we looked at the old shaft and it was about the same, so that's fine.

Columbus had to leave and I had other chores to do so we stopped. The main thing was getting the transmission into the frame with some help. I should be able to handle the rest by myself.