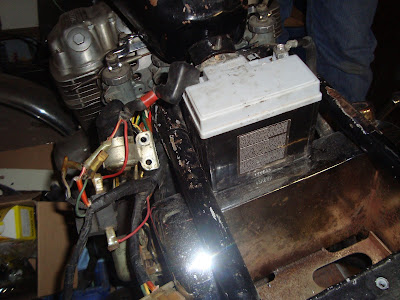

I might should have got the angled one, but we'll see.

I might should have got the angled one, but we'll see.  Here's the carb diagram.

Here's the carb diagram.  Tear it down.

Tear it down.  Bowl looks okay.

Bowl looks okay.  Rip into the petcock.

Rip into the petcock.

Fuel filter side.

Crusty.

Top half.

Crusty gasket.

Main jet and emulsion tube.

Not too bad.

Float needle and seat.

Idle adjust screw and pilot screw. The empty spot is cool because that's where the High Altitude knob goes on a Trail 90 carb. Same casting without the extra machine work.

Put everything in some carb cleaner. The float still floats so that's good.

Into the vat.

Couple of hours later.

Rinse.

I bought new stainless bolts with allen heads, because the phillips head screws are tired and the heads are half stripped.

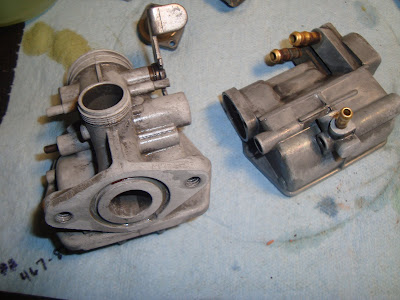

Here's the best carb kit again from dratv.com.

Filter side.

Filter.

O-ring.

Cover.

Petcock side.

The seal that guides the gas.

New o-ring here.

Tube and pilot jet.

Float needle valve and mainjet. The gasket was premature, I had to take it back off to adjust the float level.

Float on.

New idle and pilot screws and springs.

Together again. I'll put that in a bag in a drawer, because I have to rebuild everything else before I need it again. (The intake o-ring and top throttle seal are still on the bench.)

Together again. I'll put that in a bag in a drawer, because I have to rebuild everything else before I need it again. (The intake o-ring and top throttle seal are still on the bench.)