First lift the rear end up and put jack stands under it, then take the wheel off.

Take out the guide pin bolts.(13mm hexhead) You may need to use a backer wrench if everything wants to spin.

Pull the caliper off and out of the way. The pad holder stays on the wheel.

Whack the rotor until it gives loose and will come off.

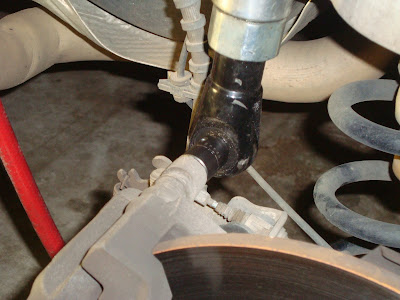

Now you need to pull the piston back in to the caliper. A regular C-Clamp won't get the job done. The piston must be screwed in the caliper not just shoved in. You need one of these. I borrowed one from my local Irish AutoZone (O'Reilly's)

New rotor on and pad holder go on.