The bolts in the right side are different lengths in different spots. I made this template from the gasket package a gasket a long time ago because I to do clutch springs for people.

Dang camera battery died. Switching to cell phone camera.

Cover on.

Bolts torqued to 88 in*lb.

The boot holder by the output shaft had a nasty burr. So ...

I filed the raised metal done so it wouldn't give me any problems.

Looking good now.

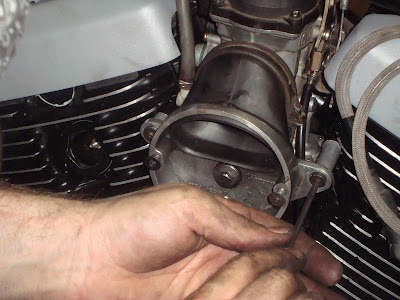

New intake o-rings.

Intake going on .

Now I just need to get the engine from the cart to the jack to the frame. I'll have to have some help.

First we spend the rear wheel ...

to get the hole in the drive shaft where can see it. More on this later.

to get the hole in the drive shaft where can see it. More on this later.

Grunt!

Drop! I mean sit down.

Line it up with frame.

This spring and pin keep the output shaft connected to the driveshaft.

The spring goes inside the output shaft the pin goes in the hole. This lines up with hole in the driveshaft.

Like this.

Once you get the shaft connected, start with the motor mounts.

Now the radiator and the subframe piece.

Looking good,

oh poop! This brake line ain't routed right. I should have left the brake and floor board connected the subframe, like when I do a clutch spring.

Take off this motormount and take the subframe piece off again.

Luckily rubbermounts allow you to pry the motor a bit and sneak the line through.

Okay now we are back together with the motor mounted and the floorboard and brake on.

Mount the dirty rectifiers.

Oh poop, again! We should have routed the hydraulic clutch correct before we bolted the motor in. It should go behind the motor and up through that hook.

Yeah there's not way we can cheat this one through. I have fresh banjo seals, because I we'll be putting steal lines on soon and I have a new seal for the leaky slave cylinder. So we took the slave cylinder off and routed the line corrected.

Here's the piston for the slave cylinder

No comments:

Post a Comment