I'm sure everyone who has been building bikes, longer than I have been alive already, knows about Big Twin lifter block bolts. So for everone else here's the story. From the 1936 Knucklehead until the 75 Shovelhead the lifter blocks had countersinks to properly position the block to the case. The case has 1/4 x 24 threaded holes. That's not a typo 1/4 x 24, not 1/4 x 20 UNC or 1/4 x 28 UNF. So those are special bolts.

This changed in 1976 when the lifter blocks had a small counterbore and would accept a standard socket head or 12 point flare head bolt in a regular 1/4 x 20 UNC thread. To properly install these blocks you need a special tapered tool with 1/4 x 20 threaded end.

So I have a case tapped for the countersunk special 1/4 x 24 bolts and 1979 lifter blocks with a counterbore only. Luckily ever more special bolts are made just for this occasion. Standard socket heads with a 1/4 x 24 thread. (I got these from a local shop that I don't like to spend money with or give shout-outs to, but they had them in stock and it was only $10)

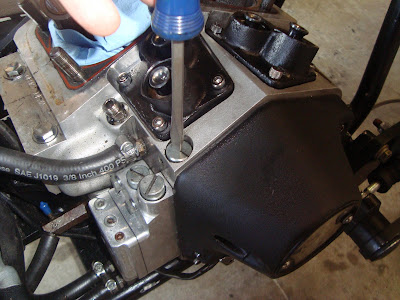

They actually make an alignment tool in 1/4 x 24 for these type of occasion, but no one had one in stock. So I used the old countersunk bolts to align the holes and blocks. I already put the gasket in here. More real Harley gaskets still available at the dealer.

Looks good.

New bolts go in and get snugged.

The other two new ones go in.

Torque per spec.

I almost forgot to clean the tappet screen. Remove cap.

Remove spring.

Remove screen.

This thing is plugged, too. This could have contributed to my tappets being galled and sticking. I should have bought a new screen, but I wasn't thinking about it.

Reverse flow(outside->in) with some air pressure got it good as new.

Assemble in reverse order and now my lifters are good to go.

I got a 1980 shovel what are the torque for those bolts ? Thanks

ReplyDelete