The Delkron cases have this nifty trap door. Up 'til now I have only cussed it as another place to leak, but now I get take it off and see how much damage was done by the wristpen coming apart.

With all the screws out a quick tap on the corner with a brass drift will get it loose.

Nasty stuff in the oil. Note the hylomar here. We had used it to try and seal the trap door before I found the correct o-ring for this style of Delkron case.

Cleaning out the cases with brake cleaner. Spray to the outside away from the rod bearings.

Now into the camchest. Off with the clear ignition cover.

Mark the ignition location in three places. I'm sure we'll check the timing again, but this will get us very close.

Take the two screws holding the ignition plate in.

Loosen the bolt with the wire holder.

I'm not planning on taking the ignition out completely out, just let it hang.

One bolt holds the ignition cup.

Now the cam cover can come off.

Don't loose the thrust washer on the breather gear.

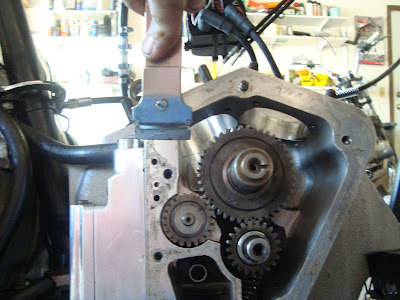

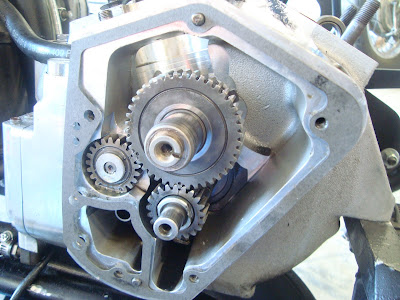

Here are the locating marks lined up on the pinion gear(lower right), cam gear(largest one), and breather gear(left side).

Breather gear needs to come out.

Finding crap from the snap ring in the breather gear.

Remember the hylomar? A whole mess of it wound up in the screen of the breather gear. This was most likely some of my sumping problems and cone cover oil leaks. This crap is really stuck in there. I basically I had to unplug each hole with a piece of welding wire.

Here's most of that snap ring.

Now to take off the lifter blocks.

Remove the screw and give it a whack.

Push the roller up so they don't fall into the camchest.

These lifters are in terrible shape. They do not slide without alot of force. I think they were this bad before the snap ring failure.

Note the little hole. Point those toward the other lifter when you install them.

All galled up. Luckily Panhead Pat had left a set of useable lifter blocks and lifters at my house a while back.

Rear block and lifter come out the same way.

The rear lifter and blocks were worse shape.

With the lifter out, the cam slides straight out.

Note the lock washer and shim. Don't loose those.

Andrews B. I always wondered what I was running.

Cam bearing is good! Time to go back up with everything.

Oil the bearing and journal before assembly.

Line up the marks.

Oil up the cleaned up breather gear.

Line up the marks and install.

Clean the gasket surface.

Oil the thrust washer surface.

Install the washer.

Oil the other side.

Oil all the bushings in the cam cover.

Gasket. Still available at the local Harley dealer.

Cover on.

One long, two medium, and two short bolt hold it on.

Short ones there.

Medium ones here. (Sorry the photo is crooked.)

Long one goes here. (Photo still crooked.)

The last bolt still had the wire holder on it. Leave this one loose for now.

Torque the bolts.

Igntion cup goes in.

Ignition plate on. Align the marks. (I didn't get a shot of the cover going on or torqueing the last cover bolt.)

Fresh o-ring here and no hylomar.

Pat works over the other lifter blocks and lifters.

Those the lifter blocks were painted silver. I want them black. So Pat did his thing.

These are looking great now, but I need a set of later style hardware to make them fit.

I have an 81 FXWG and the breather gear from what I am told is bad. Can I just take off the cam cover remove the breather and replace or do I have to go through the process in which you did in order to get it out.

ReplyDeleteAbout the only thing that needs to come off from the top end is the pushrods. The pushrods need to come out to get the tension of the cam, because one end of the cam is supported by the cam cover. You'll never get the cam cover back on if you don't pull the pushrods. The tappets and tappet blocks can stay in place, but don't pull out the cam or it you'll have to fight the tappets to get everything back together.

ReplyDeleteWhy is it that my Cam cover doesn't just slide off. Are there any retaining clips? I have heads off and no pressure on the cam from lifters. I don't understand why it is tough?

ReplyDeleteLight tapping with a rubber hammer, if you're sure all the bolts are out.

ReplyDeleteTHX for the great info!!! I gotta do this today and without these pix i wouldnt feel this confident! Thank You KINDLY :)

ReplyDelete73 flh here, my cam cover is leaking oil from the little oil weep hole in the gasket surface, installed new gasket and all. How do fix that

ReplyDelete